แผงแซนวิชโพลียูรีเทน ( พี ไออาร์ /พี คุณ แผงแซนด์วิช R - ได้กลายเป็นตัวเลือกที่เหมาะสำหรับการก่อสร้างห้องเย็น เนื่องจากมีคุณสมบัติเป็นฉนวนกันความร้อนและทนไฟที่โดดเด่น เป็นมิตรต่อสิ่งแวดล้อม และข้อได้เปรียบด้านการประหยัดพลังงานและประสิทธิภาพที่สำคัญ การเลือกความหนาที่เหมาะสมเป็นสิ่งสำคัญอย่างยิ่งต่อการดำเนินงานห้องเย็นที่มีประสิทธิภาพและมีเสถียรภาพ

แล้วจะเลือกอย่างไรให้เหมาะสม พีไออาร์ แผงแซนวิช สำหรับโครงการของคุณ? วันนี้เรามาค้นหาคำตอบไปพร้อมๆ กัน!

01 วิธีการคำนวณความหนาของแผ่น

ตามคำอธิบายวัสดุฉนวนสำหรับห้องเก็บความเย็นใน GB 50072-2021 Cold Storage Design Standard: “เมื่อใช้แผงแซนด์วิชคอมโพสิตน้ำหนักเบา เช่น แผงแซนด์วิชฉนวนหุ้มโลหะ เพื่อเป็นฉนวนกันความร้อนและแผงกั้นความร้อนในคลังสินค้าห้องเก็บความเย็น ประสิทธิภาพการเผาไหม้ของวัสดุแกนกลางของแผงแซนด์วิชจะต้องไม่ต่ำกว่า Class B1 นอกจากนี้ วัสดุแกนกลาง Class B1 จะต้องเป็นวัสดุเทอร์โมเซตติง”

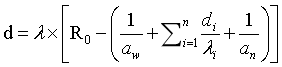

ตามมาตรฐานการออกแบบห้องเย็น GB 50072-2021 ความหนาของวัสดุฉนวนกันความร้อนสำหรับซองอาคารจะต้องคำนวณโดยใช้สูตรต่อไปนี้:

ในสูตร:

ง: ความหนาของวัสดุฉนวนกันความร้อน (ม.)

λ: ค่าการนำความร้อนของวัสดุฉนวนกันความร้อน [W/(m·℃)]

R0: ความต้านทานความร้อนรวมของซองอาคาร (m²·℃/W)

โอ้: ค่าสัมประสิทธิ์การถ่ายเทความร้อนของพื้นผิวภายนอกของซองอาคาร [W/(m²·°C)]

หนึ่ง: ค่าสัมประสิทธิ์การถ่ายเทความร้อนของพื้นผิวภายในอาคาร [W/(m²·°C)]

ของ: ความหนาของวัสดุชั้นที่ i ในเปลือกอาคารไม่รวมชั้นฉนวนกันความร้อน (ม.)

λi: ค่าการนำความร้อนของวัสดุชั้นที่ i ในเปลือกอาคารโดยไม่รวมชั้นฉนวนกันความร้อน [W/(m·°C)]

การนำความร้อน: หรือที่รู้จักกันในชื่อ การนำความร้อน หมายถึงปริมาณการถ่ายเทความร้อนต่อหน่วยพื้นที่ (1 ตารางเมตร) ต่อหน่วยเวลา เมื่อชั้นวัสดุมีความแตกต่างของอุณหภูมิ 1 เคลวิน (หรือ 1°C) ตลอดทั้งสองด้าน และมีความหนา 1 เมตร ภายใต้สภาวะการถ่ายเทความร้อนคงที่ การนำความร้อนเป็นปริมาณทางกายภาพที่วัดความสามารถในการนำความร้อนของวัสดุ และเป็นสมบัติทางความร้อนโดยธรรมชาติของวัสดุ

ค่าสัมประสิทธิ์การถ่ายเทความร้อน: หรือที่รู้จักกันในชื่อค่าสัมประสิทธิ์การถ่ายเทความร้อนแบบพาความร้อน หมายถึงปริมาณความร้อนที่ถ่ายเทต่อหน่วยพื้นที่ (1 ตารางเมตร) ต่อหน่วยเวลาในระหว่างการแลกเปลี่ยนความร้อนแบบพาความร้อน เมื่อความแตกต่างของอุณหภูมิระหว่างของไหลและพื้นผิวของแข็งมีค่า 1 K (หรือ 1°C) ค่าสัมประสิทธิ์นี้สะท้อนความสามารถในการแลกเปลี่ยนความร้อนระหว่างของไหลและพื้นผิวของแข็งโดยตรง ซึ่งแตกต่างจากค่าการนำความร้อน (ซึ่งอธิบายการถ่ายเทความร้อนภายในวัสดุ) ค่าสัมประสิทธิ์นี้กล่าวถึงการแลกเปลี่ยนความร้อนที่บริเวณรอยต่อระหว่างของไหลและของแข็งโดยเฉพาะ

ความต้านทานความร้อน: แสดงถึงความแตกต่างของอุณหภูมิที่จำเป็นต่อวัตถุหนึ่งชิ้นในการถ่ายเทความร้อน 1 วัตต์ ความต้านทานความร้อนวัดความสามารถของวัตถุหรือวัสดุในการขัดขวางการถ่ายเทความร้อน ซึ่งคล้ายคลึงกับความต้านทานไฟฟ้า (ซึ่งขัดขวางการไหลของกระแสไฟฟ้า)

02 การสาธิตการใช้งาน

ลองพิจารณาสถานการณ์ต่อไปนี้: มีอาคารเก็บความเย็นสำเร็จรูปโครงเหล็กตั้งอยู่ในพื้นที่แห่งหนึ่ง ผนังด้านนอกและหลังคาใช้แผ่นเหล็กโปรไฟล์ชั้นเดียว ขณะที่แผงแซนด์วิชโพลียูรีเทนทำหน้าที่เป็นฉนวนสำหรับผนังและฝ้าเพดานภายใน ข้อมูลต่อไปนี้แสดงไว้: อุณหภูมิเครื่องปรับอากาศกลางแจ้งโดยเฉลี่ยในช่วงฤดูร้อนอยู่ที่ 30°C และอุณหภูมิใช้งานภายในอาคารอยู่ที่ -18°C จงคำนวณความหนาที่ต้องการของแผงแซนด์วิชโพลียูรีเทนสำหรับฝ้าเพดานและผนัง

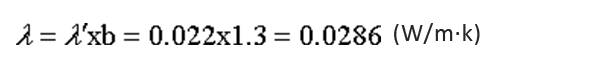

ค่าสัมประสิทธิ์การนำความร้อนที่แก้ไขด้วยโพลียูรีเทน:

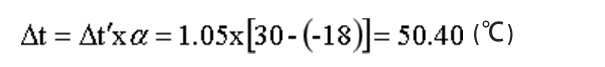

การแก้ไขความแตกต่างของความร้อนของผนัง:

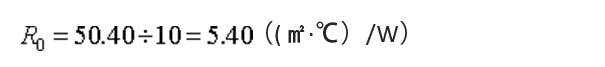

ความต้านทานความร้อนรวมของพื้นผิวผนัง:

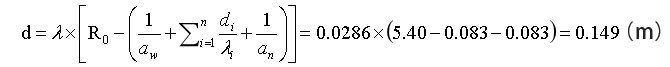

การคำนวณความหนาของวัสดุฉนวนผนัง:

ความหนาของฉนวนผนังต้องไม่น้อยกว่า 149 มม. ดังนั้นจึงสามารถเลือกใช้แผ่นฉนวนโพลียูรีเทนแบบแซนด์วิชที่มีความหนา 150 มม. เป็นฉนวนผนังได้

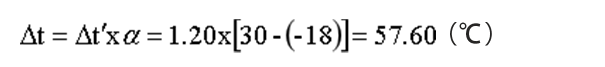

การแก้ไขความแตกต่างของความร้อนที่เพดาน:

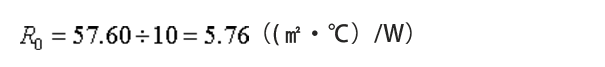

ค่าความต้านทานความร้อนรวมของฝ้าเพดานแขวน:

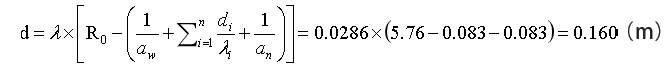

การคำนวณความหนาของวัสดุฉนวนฝ้าเพดานแขวน:

ความหนาของฉนวนฝ้าเพดานต้องไม่น้อยกว่า 160 มม. ดังนั้นจึงสามารถเลือกใช้แผ่นฉนวนโพลียูรีเทนแบบแซนด์วิชที่มีความหนา 180 มม. แทนได้

03 การนำความร้อนต่ำ ประสิทธิภาพการใช้พลังงานสูงขึ้น

เพื่อให้ได้ฉนวนกันความร้อนคุณภาพเยี่ยมในโรงงานจัดเก็บความเย็นและมอบโซลูชันประหยัดพลังงานที่มีประสิทธิภาพสูง WISKIND และ BASF ร่วมกันเปิดตัวผลิตภัณฑ์เรือธงเชิงนวัตกรรม: แผงเก็บความเย็นโพลียูรีเทนที่มีการนำความร้อนต่ำ

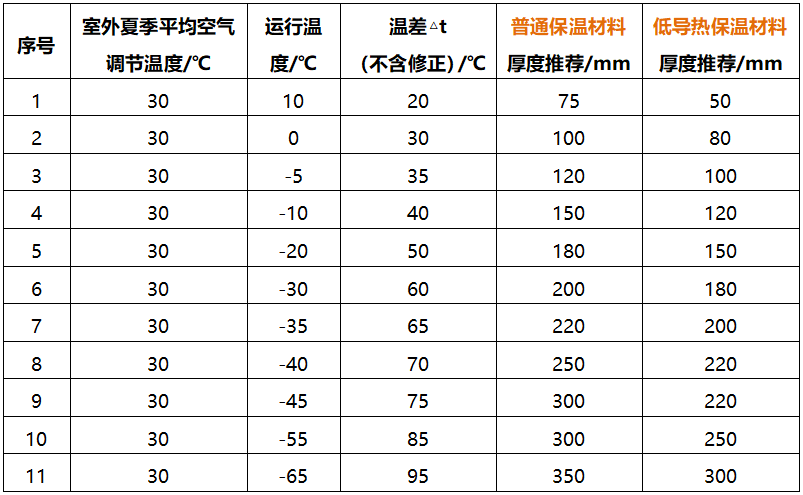

เพื่อแสดงให้เห็นความแตกต่างระหว่างแผงฉนวนโพลียูรีเทนมาตรฐานและค่าการนำความร้อนต่ำอย่างชัดเจน แผงเก็บความเย็นโพลียูรีเทน ตารางต่อไปนี้จะแนะนำการเลือกความหนาสำหรับผลิตภัณฑ์ทั้งสองภายใต้สภาวะแวดล้อมที่เหมือนกัน

หมายเหตุ:

· ตารางนี้ให้การคำนวณที่เหมาะสมโดยอิงตามข้อกำหนดเฉพาะของสถานการณ์ที่กล่าวถึงข้างต้นเท่านั้น

· โครงการจริงควรคำนวณให้เหมาะสมกับสภาพพื้นที่และสภาพแวดล้อมโดยรอบโรงงานจัดเก็บความเย็นโดยเฉพาะ

· ตารางนี้ไม่ได้แยกความแตกต่างระหว่างผนังและเพดาน โดยใช้ส่วนประกอบที่มีความต้านทานความร้อนสูงกว่าในสถานการณ์เดียวกันสำหรับการคำนวณ

· ตารางนี้ไม่รวมการคำนวณความหนาของพื้นและผนังกั้น และไม่ได้คำนึงถึงวัสดุฉนวนเพิ่มเติม (ใยหิน ใยแก้ว ผนังอิฐ ฯลฯ)

แผงเก็บความเย็นโพลียูรีเทนที่มีค่าการนำความร้อนต่ำ: เทคโนโลยีล้ำสมัยทำให้มีค่าการนำความร้อนต่ำเป็นพิเศษที่ 0.017–0.019 W/m·K ซึ่งช่วยเพิ่มประสิทธิภาพฉนวนได้ถึง 20% และเพิ่มประสิทธิภาพการทำงานของห้องเย็น เมื่อเทียบกับแผงฉนวนแบบดั้งเดิม ผลิตภัณฑ์นี้ช่วยลดการใช้พลังงานได้อย่างมาก 10%–15% รายปีสำหรับความหนาของแผงที่เทียบเท่าและพื้นที่ก่อสร้าง

โปรดอ่านต่อโพสต์อยู่ติดตามและเรายินดีต้อนรับคุณที่จะบอกเราว่าคุณคิดอย่างไร

บริการออนไลน์

บริการออนไลน์ +86-153 1435 3017

+86-153 1435 3017 market@wiskind.com

market@wiskind.com +86-153 1435 3017

+86-153 1435 3017